| Model | Power(kw) | Yield(kg/h) | Dimension(m) | Weight(t) |

| ZS200 | 7.5 | 50-80 | 1*0.44*1 | 0.4 |

| ZS250 | 15 | 100-200 | 1.12*0.44*1.06 | 0.6 |

| ZS300 | 22 | 150-250 | 1.28*0.55*1.2 | 0.8 |

| ZS350 | 30-4 | 300-400 | 1.3*0.53*1.2 | 0.9 |

| ZS400 | 37-4 | 400-500 | 1.4*0.6*1.5 | 1.2 |

| ZS450a | 45-4 | 600-800 | 1.62*0.69*1.6 | 1.5 |

| ZS450b | 55-4 | 900-1000 | 1.7*0.69*1.6 | 1.6 |

| Note: Including electric control, oil pump | ||||

|  |

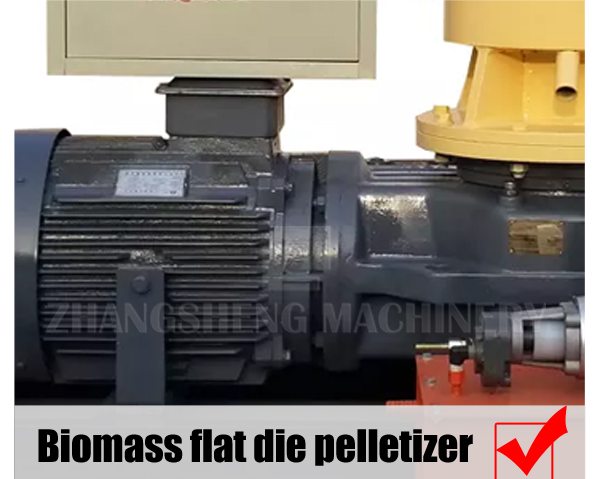

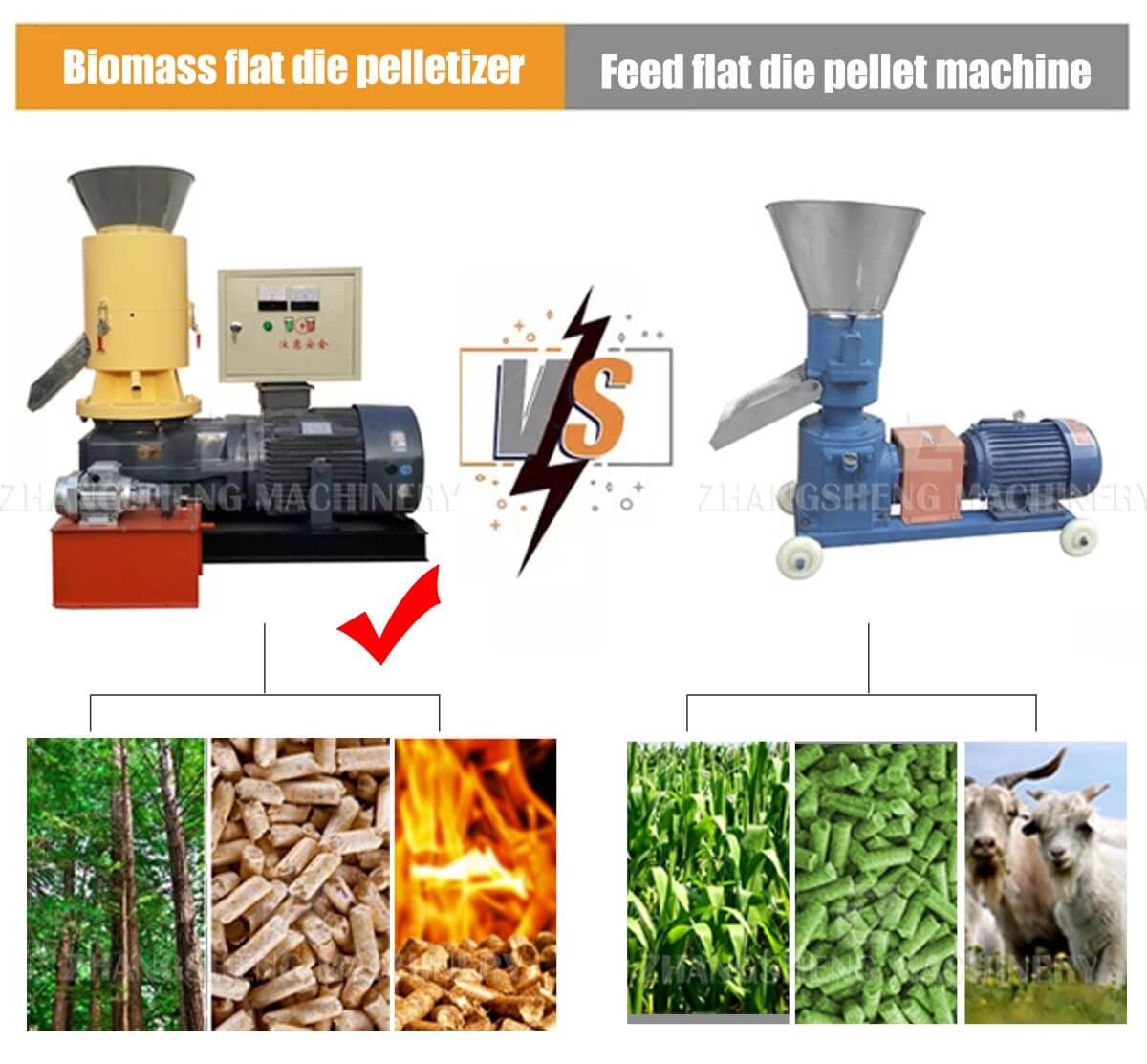

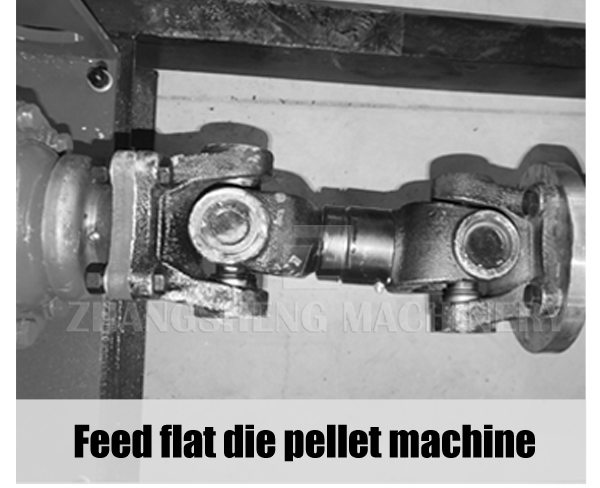

direct drive The casing of the reducer is made of high-strength cast steel, and the motor is directly connected to the hard-tooth surface reducer for smooth operation, greater extrusion force, and good biomass pellet forming effect. | universal joint drive The motor is used to connect the universal joint and the differential transmission, which has high noise, small extrusion force and poor particle forming effect. |

|  |

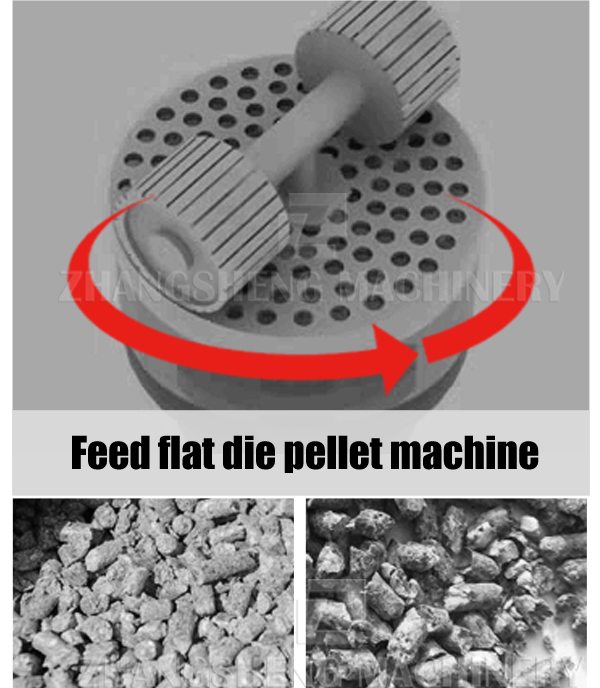

mold rotatesThe mold is static and the pressure roller rotates. The pressure roller adopts the groove width, large pressure, and good wear resistance. More suitable for making pellets from materials with low adhesion rate such as wood chips and straw. | mold stationary When the mold rotates and the pressing wheel is stationary, the extruded particles will be beaten twice with the mold, resulting in poor particle forming effect. |