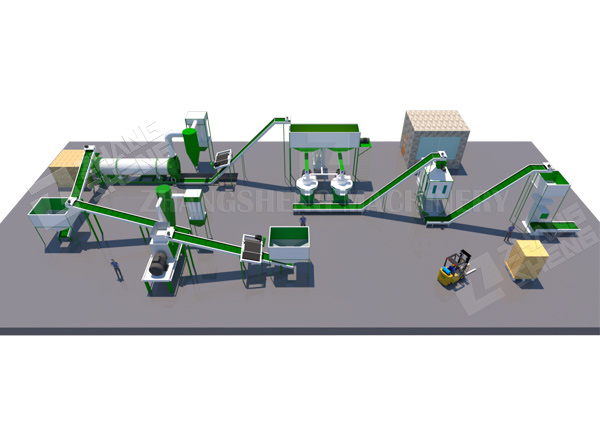

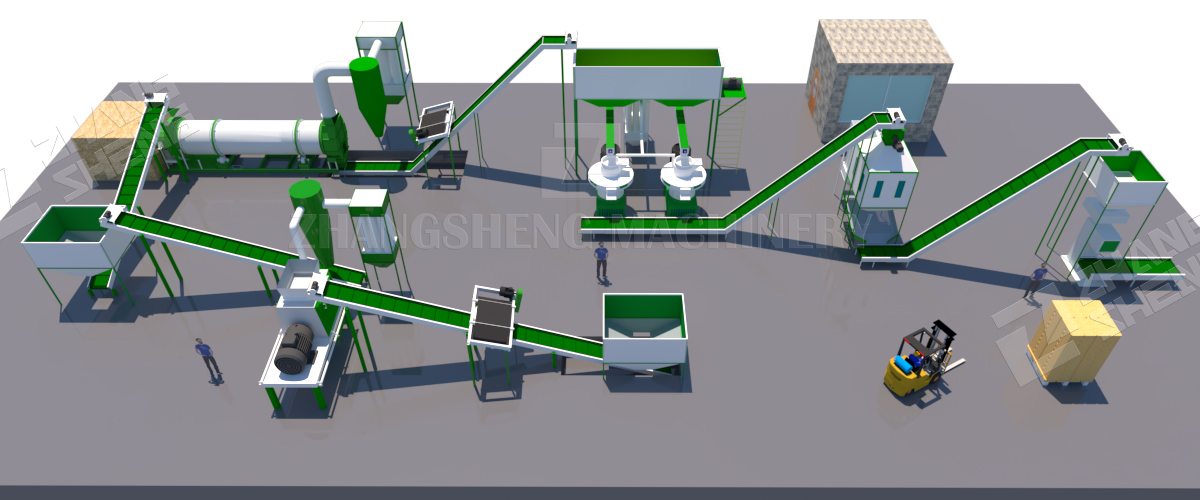

Process : Wood sawdust making, drying (optional), pelletizing, cooling, packaging

Capacity : 1-10t/h

Outsize : 6mm, 8mm, 10mm, 12mm pellets

various straws

Email: market@tiroxcorp.com

Straw is an agricultural by-product consisting of dry straw from which grains and chaff have been removed. Straw pellets have the advantages of renewable, emission reduction, low pollution and economy. Unlike fossil fuels, straw resources are endless as plants grow.

ZhangSheng Straw pellet production line integrates all processes from raw materials to pellets, including crushing, drying, pellet making, cooling and packing, with an output of 1 to 10 tons per hour.

Straw pellets can not only alleviate energy shortages, but also one of the most effective ways to achieve renewable energy and carbon reduction goals.

The value of straw pellets has not been taken seriously. There is still a large amount of crop straw that is neglected and directly burned. In a large agricultural country with rich straw resources, starting a straw pellet production line is indeed a very promising project. Under the high energy cost, straw pellet is a very good thermal energy source, straw pellet line is a promising and lucrative project.

The cleanliness of our pellet production line can reach 98%, effectively ensuring the cleanliness of the workshop environment.

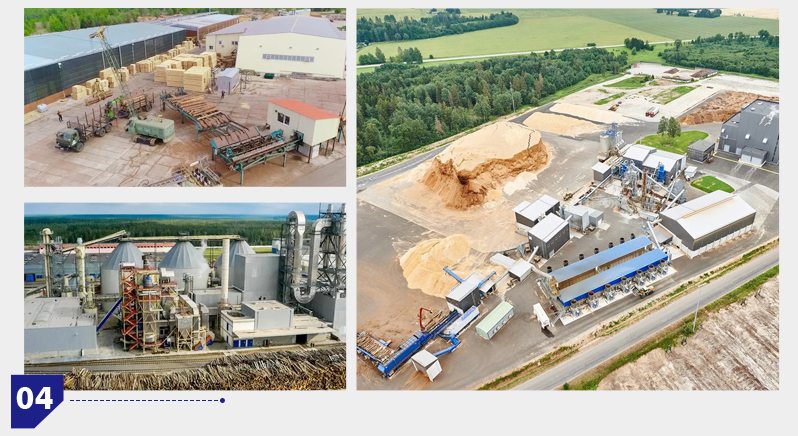

We are not just equipments supplier, we can provide tailor-made solutions according to customer requirements.

Our expertise and extensive experience help clients optimize their operations, help them improve economic benefits.

We fully understand industry trends, and work with partners to build future-oriented biomass wood pellet plants.

Note: This is a conventional simple biomass pellet production line, we can customize different pellet production plans for you according to different sites, raw materials, output and budget. As a leading pellet machine manufacturer in China, ZhangSheng has rich experience in pellet machine manufacturing, and can build a unique pellet mill for you according to the actual situation.

Are you a factory or a trading company?

We have our own factory. we have over 20 years of experience in the pellet line manufacturing. "Market our own products" reduces the cost of intermediate links. OEM available according to your raw materials and output.

Which raw materials can be made into biomass pellets? If any requirements?

Raw material ca be wood waste, logs, tree branch , straw, stalk, bamboo, etc including fiber.

But the material for directly making wood pellets is sawdust with a diameter of no more than 8mm and moisture content of 12%-20%.

so if your material is not Sawdust and moisture is more than 20%, you need other machines, such as wood crusher,wood hammer mill and dryer etc

I know very little about pellet production line, how to choose the most suitable machine?

Do not worry. We have helped a lot of beginners. Just tell us your raw material, your capacity (t/h) and the size of the final pellet product, we will choose the machine for you according to your specific situation.

Our workers don't know how to operate the pellet mill, what should I do?

Our engineers will guide the field workers how to install the machine and arrange the workshop layout. Our engineers will then test run the live production line and train your workers how to operate it.

What payment term do you accept?

We support various payment methods, we can accept 20%-30% as a deposit. Customer pay the balance after the end of production and inspection. We have more than 1000 square meters of spot stock workshop. It takes 5-10 days for ready-made equipment to be shipped, and 20-30 days for customized equipment. We will do our best to deliver as soon as possible.

Where is the market for the product and where is the market advantage?

Our market covers the entire Middle East and European and American countries, and exports to more than 34 countries. In 2019, domestic sales exceeded RMB 23 million. The export value reached 12 million U.S. dollars. And the perfect TUV-CE certificate and reliable pre-sales and after-sales service are what we have been working hard to do.